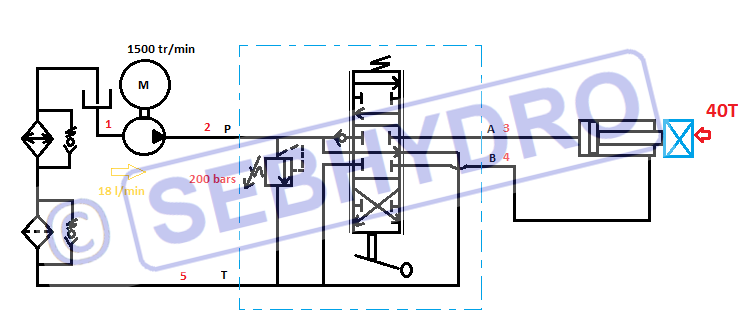

2-Pressure calculation

2-1 Piston surface

S = π*R²

S : Surface in cm².

R : Piston radius in cm (16/2=8cm).

S = π *8²

S= 200,96 cm².

2-2 Pressure required

P = F/S

P : Pressure in bar.

F : Force in daN or Kg.

S : Piston surface in cm².

P = 40000/200.96

P = 199 bars : rounded to 200 bars.

We will take an external gear pump installed under load. (Tank above the pump).

3- Flow Calculation

3-1 Cylinder speed

The length of the cylinder 30 cm or 0.3 m must be exit in 20 seconds.

Is : 0.3/20 = 0.015 m/s

3-2 Flow required

Q = 6*S*V

Q : Flow in l/min.

S : Piston section in cm².

V : Cylinder speed in m / s.

Q = 6*200.96*0.015

Q = 18.08 l/min rounded to 18 l/min.

4- Calculation Displacement of the pump

The electric motor runs at a speed of 1500 rpm.

Q = q*N/1000

Q : Flow in l/min.

q : Capacity of the pump in cm3 / revolution.

N : Rotation speed in rpm.

18 = q * 1500/1000

18 = q* 1.5

q = 18/1.5

q = 12 cm3/t.

5- Directional valve size

The maximum flow rate through the directional valve is the pump flow multiplied by the cylinder section ratio.

Section Ratio: The difference between the piston surface and the annular surface.

Q = 18 *2 = 36 l/min.

We will choose a monoblock directional valve type 6/3 open center can pass 40l / min. The pressure relief valve is integrated in the directional valve.

6- Tank size

In industry, the size of the tank is 4 to 5 times the flow of the pump.

In on-board circuits (public works- agriculture) the size of the tank is between 0.8 to 2 times the flow of the pump.

More precisely, the tank must contain the useful volume (volume of the cylinders + pipes) + the tidal volume (return volume of the cylinders + volume of the accumulators) + the volume of sky (15% of the useful volume + tidal range).

We will take a tank of 35 l.

7- Power of the electric motor

P = p * Q / 540

P : Power in KW.

p : Pressure in bar.

Q : Flow in l / min.

P = 200 * 18 / 540

P = 6.66 KW we will take a standard engine 7.5 KW.

8- Power of the exchanger

If the installation only works for a few minutes a day, it is not necessary to install an oil cooler.

Otherwise, it is advisable to take an exchanger that can dissipate 35% of the installed power.

6.66 * 35/100 = 2.33 KW.

9-Pipe dimension

The dimensioning of the inside diameter of the pipes is done thanks to the chart below.